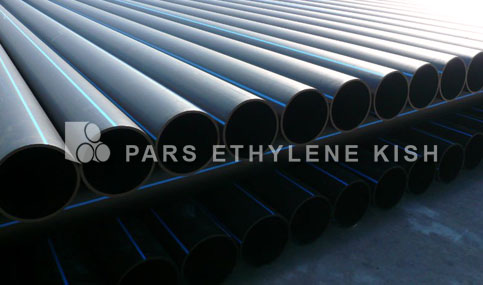

What does PE 100 mean?

PE 100 pipe specifications

The polyethylene pipes were being produced with pipe grade polyethylene which is known as PE 100 , PE 80 and PE 63 and supplied to the market, the only difference was in density and concentration. Nowadays, with the developments in the technology and higher standards only the PE 100 grade is remaining and the other grades have been put out of the production cycle.

polyethylene pipes with PE 100 grade materials are lighter and more robust than other grades of polyethylene materials and hence is cost effective.

Advantages of using PE 100 materials:

-

Better processability and more output and less production costs

-

Better flexibility for winding, maintenance and installation of the pipes, ISO 13469

-

More resistance against slow crack propagation and high safety factor for the product (SCG test)

-

More resistance against rapid crack propagation (RCP test, ISO13469, Version 1996).

-

More hydrostatic resistance of PE 100 in comparison with PE 80 (tested based on ISO 1167 standard)

Better processability

This phenomenon has its roots in the production method of PE 100 , such that the molecular weight in these polymers follow a bimodal distribution. In fact, with such distribution would enable an easier processability of the materials due to low molecular weights, one can ensure the engineering properties of the final product because of presence of high molecular weights and provides a of desired physical mechanical properties along with easy production conditions all together.

Actually using Bimodal PE 100 enables the customer to have an easier production process while preserving engineering properties including toughness, stiffness and acceptable long term mechanical behavior which finally shows up in lower production costs and lower prices for the final product.

Better flexibility

Rich engineering properties of PE 100 versus PE 80 enables to produce a pipe with less thickness in a constant working pressure while preserving mechanical properties at a determined level which results in a product with more uniform properties in the pipe thickness. Also high creep resistance of this grade than PE 80 provides us with less subsidence or sagging in the pipes with big diameters.

As a conclusion, using PE 80 grade ensures final properties of the product in production of the pipes with big diameters, in high working pressure and high reliability.

High resistance against slow crack propagation

Technically, the pipe performance in long term is estimated with its resistance against slow crack propagation, because the presence of tiny cracks while installation or transportation of the pipes is inevitable. New variants of PE 100 predicts a wider temperature ranges for pipe usage which is available due to transmission of temperature of fracture mechanism type (from tough fracture to crispy fracture) to higher temperatures in comparison with PE 80. It is obvious that the acceptable mechanism for fracture of the polyethylene pipes is tough fracture (canary tip).

High resistance against rapid crack propagation (RCP)

Under internal pressure of the pipes and the potential energy stored there, it is highly probable for cracks to propagate rapidly (at about 200-400 meters per second) and it is also inevitable. In order to cope with such phenomenon, it is important to identify the effective factors, we know that RCP fracture is influenced by pipe diameter, wall thickness and internal temperature and pressure of the pipe.

Increasing the thickness in some specific size of the pipe (in a specific application temperature) will make the RCP occurrence even more probable and hence using PE 100 materials which enables reducing the wall thickness while preserving engineering properties is considered a development in order to improve the mechanical behavior of the pipe. The graph below depicts a comparison of different generations of polyethylene in this respect (in different diameter to wall thickness ratios).

High hydrostatic resistance

The most important property of the pipes under pressure is their resistance against hydrostatic pressures which represents the lifetime of the pipe with respect to the internal pressure applied. In this test the toleratble pressure in different temperature and time intervals is investigated on the pipe under survey for which a comparison based on the type of the materials will be provided in the following:

(the reported values show the applied tension in Mega Pascal).

HDPE pipe sizes in inches

1.2 inch hdpe pipe

3.4 inch hdpe pipe

1 inch hdpe pipe

1-1.4 inch hdpe pipe

2 inch hdpe pipe

2-1.2 inch hdpe pipe

3 inch hdpe pipe

4 inch hdpe pipe

5 inch hdpe pipe

5-1.2 inch hdpe pipe

6 inch hdpe pipe

7 inch hdpe pipe

8 inch hdpe pipe

9 inch hdpe pipe

10 inch hdpe pipe

11 inch hdpe pipe

12 inch hdpe pipe

14 inch hdpe pipe

16 inch hdpe pipe

18 inch hdpe pipe

20 inch hdpe pipe

22 inch hdpe pipe

25 inch hdpe pipe

28 inch hdpe pipe

32 inch hdpe pipe

36 inch hdpe pipe

40 inch hdpe pipe

48 inch hdpe pipe