The Leavenworth Water Department Excavates 100-Year-Old Water Mains, Undergoes a Major Replacement Program with Plastic Pipe

As the oldest city in Kansas, Leavenworth is full of history — in particular, American military history. Situated on the Missouri River about 25 miles northwest of Kansas City, Mo., the city is home to Fort Leavenworth, the oldest active U.S. Army post west of Washington, D.C., built in 1827.

The fort houses the Military Corrections Complex, which co mprises the U.S. Disciplinary Barracks, sometimes abbreviated USDB, or called simply, Leavenworth. The USDB is the only maximum security prison of the U.S. Department of Defense and has been operated in Leavenworth, since 1875 — 20 years after the city was incorporated.

mprises the U.S. Disciplinary Barracks, sometimes abbreviated USDB, or called simply, Leavenworth. The USDB is the only maximum security prison of the U.S. Department of Defense and has been operated in Leavenworth, since 1875 — 20 years after the city was incorporated.

Similar to these military facilities, Leavenworth’s infrastructure — specifically its water pipes — has also been in use for more than a century. With aging infrastructure failing at a rapid rate, it’s no surprise that old cities such as Leavenworth might be at a greater risk, and in recent years, the city’s water department has been busy developing a replacement plan for many of its pipe networks.

While the city has taken a proactive approach to the rehabilitation and replacement of water lines, Leavenworth exemplifies a unique case study in which many pipes in the ground were found to be in good working condition, some of which were determined to be well over 100 years old. The city has also implemented trenchless technologies such as pipe bursting, of which the city does in-house, as well as horizontal directional drilling for the replacement of water lines. The water department was also forced to get creative in repairing a transmission main that was severely damaged when the Missouri River experienced one of the worst floods in history two years ago.

Replacement Program & 100-Year-Old Cast Iron

The City of Leavenworth has about 180 total miles of transmission lines, water mains and service lines. About half of that pipe will likely need to be replaced over the next 20 years, according to John Kaufman, general manager of the Leavenworth Water Department, which serves about 50,000 people.

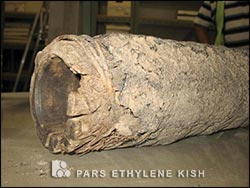

Since the 1990s, the water department has consistently evaluated and replaced water lines, but in 2005 it began a more proactive makeover of the system , replacing mainly cast iron pipe with high density polyethylene (HDPE) pipe. Kaufman says according to very accurate records kept by the city, much of the cast iron pipe that has been replaced was originally installed in 1882.

, replacing mainly cast iron pipe with high density polyethylene (HDPE) pipe. Kaufman says according to very accurate records kept by the city, much of the cast iron pipe that has been replaced was originally installed in 1882.

“The cast iron pipe was great pipe and [in the late-1800s] it was the technology of the day,” Kaufman said. “When it was installed, people didn’t understand the importance of bedding the pipe in sand, and they certainly didn’t have polywrap in 1882 either. In general, the older large diameter cast iron pipe is still in pretty good shape.”

In terms of pipe size, the cast iron pipe was anywhere from 2 to 18 in. in diameter. The city also has some ductile iron pipe in the ground as big as 24-in. diameter, but the cast iron pipe seemed to have the most longevity, with much of it still in use.

“Last year, we cut into a 16-in. line that was installed in about 1909,” he said. “It was actually bedded in coal, and it was in almost mint condition. The inside looked like new and the outside was just slightly pitted.” Kaufman attributed several factors to the pipe’s longevity, noting that it was well drained, had little standing water around it and was sand-cast pipe rather than pit cast and had different metallurgy.

On a separate occasion, the water department discovered two pipes that are part of a network of large diameter transmission lines near its northern water treatment plant that were later determined to be recycled material from the civil war era. The treatment plant manager has old records of where materials originated from, and the transmission lines were projected to be used as early as the 1860s.

Source: http://www.uimonline.com