Hydroelectric Power Plant’s Steel Cooling Water Piping System Replaced with HDPE Pipe

Hydroelectric power, an alternative renewable energy, uses the gravitational force of falling or flowing water to produce electric power. A hydroelectric power plant produces no direct waste and has a much lower output level of greenhouse gas emissions, such as carbon dioxide (CO2), than power plants that use fossil fuels.

The Alabama Power Company’s Bouldin Hydroelectric Generating Plant, which uses a dam to generate electricity, had an existing steel cooling water piping system that was in bad condition. Cooling water piping systems cool power generators more efficiently, and therefore are essential to a hydroelectric power system. The steel pipe, however, inhibited water flow because it was rusty and corroded.

To prevent future problems with rust and corrosion, Fred Hollis, the hydro mechanical retrofit engineer for the Alabama Power Company, decided to replace the existing pipe with high-density polyethylene (HDPE) pipe because of the material’s long-lasting, leak-free and corrosion-resistant features.

Piping Materials and System Design

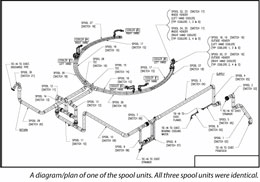

The company was replacing three cooling water pipe units with HDPE pipe . The new piping was designed as a complex system of pipe that included approximately 30 spool pieces per unit, all with several bends and curves. In the design, cooling lake water comes into the plant through an initial spool, making its way through a couple of valve stations (see diagram). The flow can be reversed (near spool 11) to help flush the coolers. Around spools 28 and 25 (supply and return), water enters the cooling room and goes through six coolers. Water then exits into the river below the dam (at spool 30). Jimmy Bauch, regional sales manager for ISCO Industries, worked with the power company to supply the HDPE pipe spools and other materials. ISCO Industries prefabricated all the spool units at its Houston, Texas facility. This was done to speed up installation by eliminating onsite welding, to reduce potential costs associated with onsite fabrication and to minimize safety hazards on location. Prefabricating the spools in a controlled environment, rather than in field conditions, also ensured the quality of the product. The three spool units were made of PE3408 three-inch, four-inch, six-inch and 10-inch pipe. All three were identical.

Installation HDPE Pipe

The demolition of the old deteriorated steel cooling water pipeline, fabrication of the new HDPE spool units and their installation had to take place in a way that was both timely and organized – another reason prefabrication of the spools was an essential part of the project.

Also, the demolition and installation could not disrupt the power plant from its main function, therefore only one of the plant’s generating units could be down at one time.

ISCO Industries served as the lead on the job, working in conjunction with a mechanical contractor and another contractor to remove the old steel cooling pipe and then to replace it with the new prefabricated HDPE pipe spoolsystem.

Demolition began on the existing pipe as soon as one of the power generating units was shut down, secured and locked/tagged out. The fabrication of the new replacement HDPE pipe took place at ISCO’s facility during the time the existing steel pipeline was demolished.

The fabrication was timed in such a way that the spools arrived on site for installation as the old pipe was removed.

The HDPE pipe was installed above ground so it was necessary to fully use the pipe’s bending radius to handle the unique situation. Unlike steel pipe, HDPE pipe is veryflexible.

Once a new HDPE pipeline was installed, the unit was watered down and then brought back online. This happened for each of the three spool units, one at a time, to avoid shutting down more than one power generating unit during installation.

All three spool units came online without any issues or leaks. The project was completed safely and ahead of schedule. Now, the power plant has a new, fully functioning HDPE pipe cooling system that will not rust or corrode.

source : www.isco-pipe.com