.jpg)

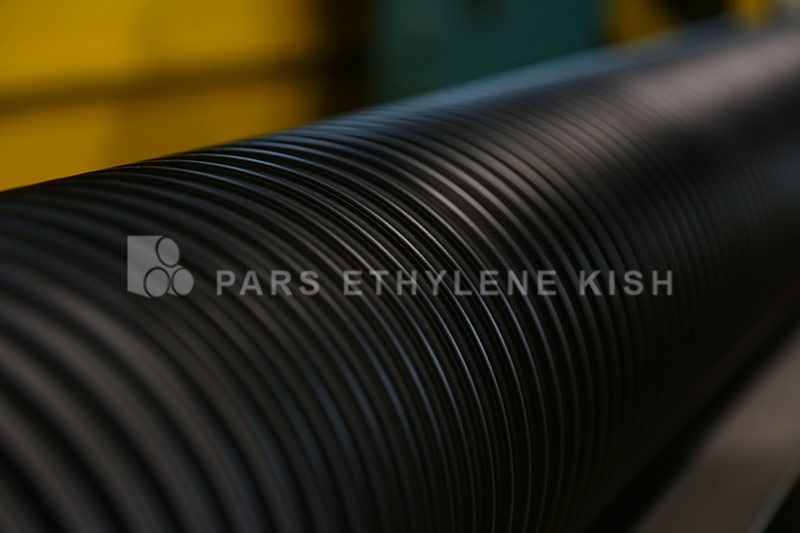

Corrugated pipes

Double wall Polyethylene Pipe

There are multiple applications for corrugated pipes of Parsethylene Kish Corporation such as drainage , industrial and domestic sewage ; however we can also apply them in large urban projects.

Given the numerous benefits of polyethylene pipe and PE fittings , costs of these large projects are reduced as well.We supplier HDPE pipe in the Middle East and Iran with the highest quality

Parsethylene Kish PE pipes and fitting for sewage usages , Advantages :

-

High resistance to corrosion

-

Wide temperature range for function

-

Easy loading and installation because of high flexibility

-

Suitable fittings with integral sealing

-

High strength of welded joints equal or even higher than pipes due to homogeneity of welded area and pipe.

-

Better hydraulic behavior

-

High resistance to abrasion

-

Light weight and easy transportation

-

Low costs for transportation & installation

-

Corrugated pipe production line

-

Corrugated pipe production line

-

Corrugated pipe production line

-

Corrugated pipe production line

-

Corrugated pipe production line

Roughness of inner walls of corrugated PE pipes and fittings cause increase in ……… and decrease in pressure drop. This property however is not of high note in swage (because there is no pressure in the waste water path) but it actually doesn’t allow waste mass & particles stick to the interior wall of sewing pipes thus no interior cleaning is required and the pipes are self maintained.

Features and Advantages of corrugated pipes

Corrugated Pipes; Application infrastructure, irrigation systems, sewerage lines, household connections, storm water and industrial applications, has a wide network such as drainage systems and treatment plants. Corrugated Pipes due to the special design of the external surface which is resistant to heavy traffic loads.

Better quality and more durable spiral corrugated pipes - larger diameter pipes with high strength and light weight are also easily transported and installed quickly. Installation time is reduced. Assembly costs are reduced by Larger diameter corrugated pipes. With a low coefficient of friction it does not generate sludges and debris in the tube.

Table of dimensions -double wall pipes- Parsethylene Kish.

|

Standard

|

Ring

stiffness

|

Outside

Thickness

|

Inside

Thickness

|

Outside

Diameter

|

Inside

Diameter

|

|

Din

|

Kn/mm2

|

mm

|

mm

|

mm

|

mm

|

|

Din 16961

|

31.5

|

1.1

|

1.3

|

234

|

200

|

|

Din 16961

|

31.5

|

1.3

|

1.6

|

292

|

250

|

|

Din 16961

|

31.5

|

1.8

|

1.8

|

368

|

315

|

|

Din 16961

|

31.5

|

2.2

|

2.4

|

468

|

400

|

|

Din 16961

|

31.5

|

3.35

|

3.1

|

557

|

500

|

|

Din 16961

|

31.5

|

3.6

|

3.7

|

708

|

600

|

|

Din 16961

|

31.5

|

4.7

|

4.2

|

827

|

700

|

|

Din 16961

|

31.5

|

5.6

|

5

|

1004

|

850

|

|

Din 16961

|

31.5

|

6.6

|

5.7

|

1182

|

1000

|

For further information contact technical unit , Parsethylene Kish Corporation.

• Functional Principles of Corrugator Technology - Article Data »