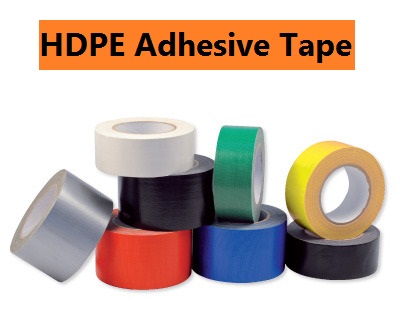

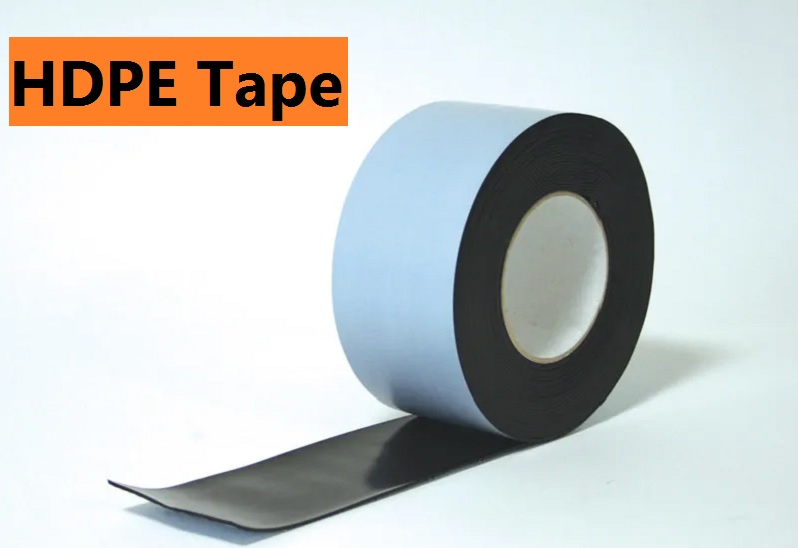

HDPE Tape

HDPE adhesive tape, which stands for High-Density Polyethylene adhesive tape, is a type of hot melt tape known for its heavy-duty water resistance. It's made from HDPE fabric, which offers several advantageous properties:

-

**High Tensile Strength:** HDPE fabric is strong and resistant to stretching or tearing, providing the tape with the ability to withstand high levels of stress.

-

**High Binding Capacity:** The tape has a strong binding capacity, making it effective for securely joining surfaces.

-

**Strong Adhesion:** The adhesive used in HDPE tape offers strong adhesion, allowing it to stick well to various surfaces.

-

**Water and Moisture Proofing:** The combination of HDPE fabric and the adhesive's properties make the tape resistant to water and moisture, making it suitable for applications where protection against these elements is crucial.

HDPE adhesive tape is commonly used in situations where a durable and water-resistant adhesive solution is needed. It finds applications in industries such as construction, packaging, outdoor signage, and more.

The importance and benefits of polyethylene tape

Polyethylene tape offers several important benefits and advantages due to its unique properties, making it a versatile choice in various industries. Here are some of its key importance and benefits:

-

**Physical Resilience:** Polyethylene tape is known for its durability and resistance to impact, bending, and stretching, making it suitable for applications in challenging environments.

-

**Chemical and Moisture Resistance:** The tape's resistance to chemicals and moisture is crucial for applications that involve exposure to corrosive substances, water, or humid conditions.

-

**Flexibility and Conformability:** Its flexibility and ability to conform to irregular surfaces ensure that it can be applied smoothly to a wide range of materials and shapes.

-

**Ease of Application:** Polyethylene tape is easy to cut, handle, and apply, making it convenient for various tasks. Its adhesive properties allow for secure attachment to surfaces.

-

**Abrasion and Tear Resistance:** The tape's resistance to abrasion and tearing makes it suitable for applications where surfaces need protection against wear and tear.

-

**Electrical Insulation:** Due to its insulating properties, polyethylene tape is commonly used in electrical applications to prevent short circuits and insulate wires.

-

**Environmental Friendliness:** As a type of plastic, polyethylene is considered an environmentally friendly alternative to materials like PVC.

-

**Corrosion Protection:** In the form of corrosion-resistant tape, polyethylene tape can provide long-lasting protection to pipelines and other metal surfaces.

-

**Customizability:** Polyethylene tape is available in various sizes, colors, and types to suit specific needs and applications.

-

**Versatility in Applications:** From packaging and surface protection to electrical insulation and color coding, polyethylene tape is utilized in diverse industries, enhancing its utility and importance.

-

**Cost-Effectiveness:** The tape's reasonable cost, coupled with its durability and longevity, makes it a cost-effective solution for many applications.

-

**Safety and Compliance:** Polyethylene tape's low chloride and halogen content make it suitable for applications in nuclear power plants and other environments where these factors are crucial.

In conclusion, the benefits and importance of polyethylene tape stem from its ability to provide protective solutions across a wide range of industries and applications. Its combination of physical properties and customization options make it an essential tool for preserving, securing, and enhancing materials and surfaces.

Read More: