Application Of Polyethylene pipes in Floor Heating

PEX Pipe in Floor Heating

With ever increasing population and also reducing energy resources, the efficient consumption of energy is obvious . In this regard , the role of efficient heating systems of buildings and residential complexes is an important and advised one in the control and optimization of energy consumption.

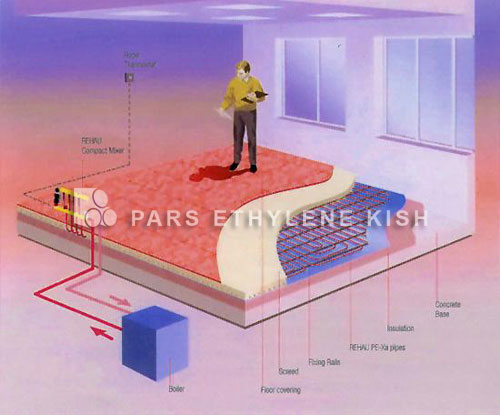

Thermal heating system from the floor in radiation form has a large share in its heating process

heating system from the floor is known as the most comfortable , the healthiest and the most natural method for heating . As people on a cold winter day feel heat by radiation of the sun. In this procedure they receive the heat by radial heat transfer from the floor that is truly much more comfort feel.

When a group of interconnected of pipes are put to gather to transmit the heat evenly among the levels , refers to a system called the heat system of floor.

In such systems , ground water from 40 to 45 degrees Celsius , is distributed through power houses in a flexible way .In the heating system from floor heat transmitted to environment in radiation form .

one of the other advantages of floor heating system is in the meted of melting snow and ice , As this meted can be used for melting ice or snow existing on the places that quick and easy access is requires such as pavements , loading ports , roads , entrances of buildings and hospitals , plane lands and land sports including football field ,and etch . well as reducing the cost of snow removal and salt down , this method will be very effective in keeping the structure of the said items .

PEX polyethylene pipes in floor heating

Having excellent mechanical properties ,Polyethylene has changed to the first choice for implementation of heating projects from the floor.PE pipes of floor heating are produced in two models of PEX and PE-RT .

PEX Pipe

PEX Pipe is a hard heating polymer that is attained after going under the procedures called cross-linking and creating structural changes in heavy polyethylene (HDPE) . Cross-linking is implemented through different methods.

In all methods based on different technologies , the purpose is to create connection and communication among single branches existed in a mass form . The number and density of these connection bands guarantee the percentage of being network . This percentage distinct the type of paces from one to another or even paces are available under one name .

WHAT IS PE-RT ?

Polyethylene of pipe of raised temperature resistance of 8 is a beautiful, glassy and transparent one that is also called octane polyethylene. It is not too long from the production of PEOC. And only just several companies in the world are applied to produce it. This polymer with initial goal of replacing is produced ,but due to enduring less temperature and pressure and the lack of high resistance against chlorine ,has so far failed to rave high share compare to other pipes equipment.

THE ADVANTAGES ITEMES OF PE-RT

The produced pipes with this polymer character is allowed to use in irrigation and thermal systems of buildings accordance with the relevant standards ,and topic 16 of national building regulations up to 60 degrees.

Some of the mostly used Pars Ethylene Kish products

Pars Ethylene Kish produces widespread range of polyethylene pipes, fittings and manholes with the best material and modern German machineries which meet the needs of engineering plans and projects.

Today, Pars Ethylene Kish polyethylene piping systems have been used in the most firefighting systems' projects, water transmission pressure projects and urban and industrial sewage transmission systems and also natural gas transmission in the industrial and chemical environments, telecommunication projects and cable covering.

New generation of Pars Ethylene Kish corrugate pipes produce by using the advanced and modern production of double-wall corrugate polyethylene pipes' production line in the world. This production line is totally made in Germany and enjoys advanced German engineering.

Spiral polyethylene pipes can be used in cases when weight of soil exceeds the corrugate pipes threshold. Spiral polyethylene pipes can also be used in the liquid transmissions or air transmission canals on the surface or under the ground in low pressures.

Drainpipes of this company are only produced pipes in Iran which are made completely according to the Germany DIN 1187 standard. It has six holes in each row and their drain surface is better compared to other pipes.

Polyethylene hand holes have diverse applications like protective box of fittings, counter box, monitoring box in cable lines, visit box in water, oil and gas lines. Pars Ethylene Kish hand holes produce depending their application in different dimension, size and forms.

Polyethylene manhole is another product of Pars Ethylene Kish Company which is made of best raw materials and best design relative to similar samples. Regarding widespread application pf polymer products in different industries throughout the world, it can be a suitable alternative for concrete manholes and other manholes constructed with masonry aggregates.

Polyethylene pipelines in different projects need polyethylene fittings that these fittings will be different regarding type of project and application.