What is Ultrahigh Molecular Weight Polyethylene (UHMWPE) and Advantages of UHMWPE

Introduction

When it comes to engineering plastics, Ultrahigh Molecular Weight Polyethylene (UHMWPE) stands out as a remarkable material with a wide range of applications. In this comprehensive guide, we will delve into the world of UHMWPE, exploring its properties, manufacturing processes, and diverse applications across industries. Whether you are an engineer, a manufacturer, or simply someone curious about this remarkable material, this article will provide you with valuable insights.

1.1 What is Ultrahigh Molecular Weight Polyethylene (UHMWPE)?

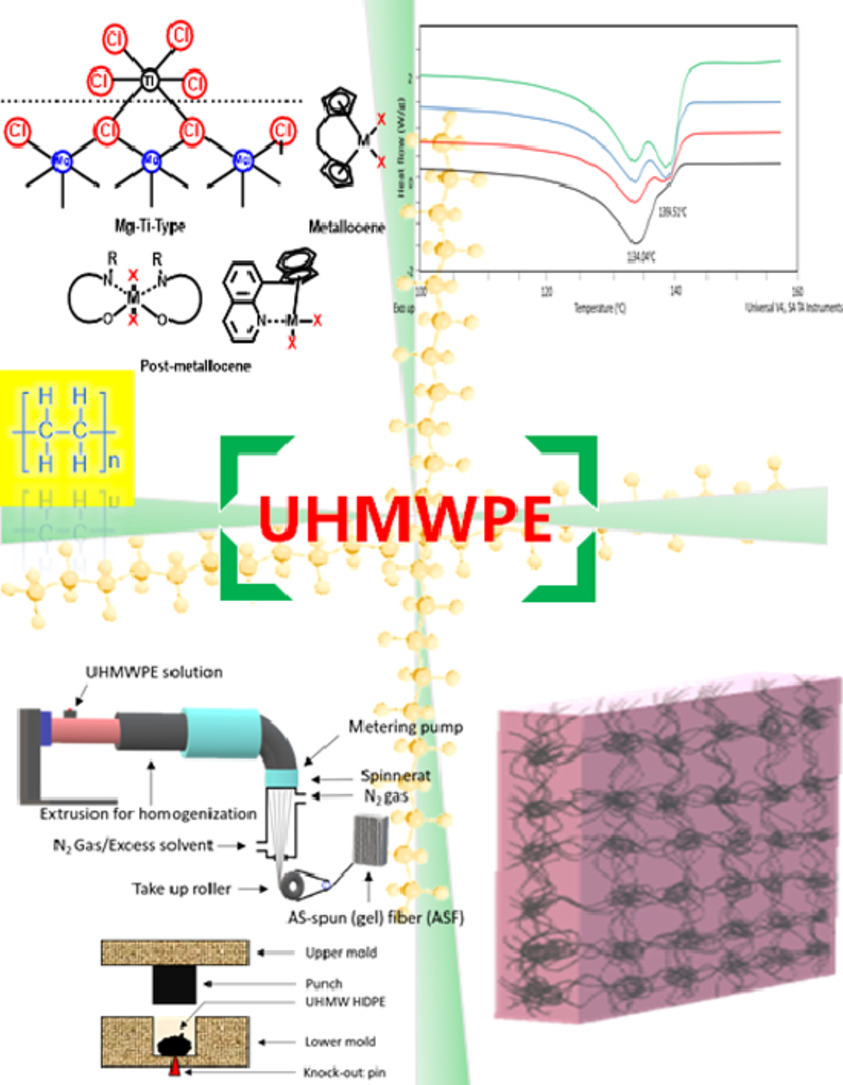

Ultrahigh Molecular Weight Polyethylene (UHMWPE) is a type of polyethylene characterized by its exceptionally high molecular weight. With molecular weights ranging from 3 to 6 million grams per mole, UHMWPE exhibits unique mechanical, chemical, and thermal properties that it apart from other plastics.

The structure of UHMWPE consists of long chains of polyethylene molecules, densely packed together, which contribute to its outstanding strength and toughness. These chains are longer compared to other forms of polyethylene, giving UHMWPE its "ultrahigh" molecular weight.

1.2 Importance and Applications of UHMWPE

The importance of UHMWPE lies in its versatility and its ability to address complex engineering challenges. Its exceptional properties make it an ideal choice for a wide range of applications across various industries.

In the medical and healthcare industry, UHMWPE is widely used in orthopedic implants, such as hip and knee replacements. Its biocompatibility, low friction coefficient, and wear resistance make it an excellent material for joint replacements, providing patients with enhanced mobility and durability.

UHMWPE also finds extensive use in automotive and transportation applications. Its lightweight nature, impact resistance, and ability to withstand harsh environments make it suitable for components like gears, bearings, and liners in automotive systems. Additionally, its low coefficient of friction contributes to reduced fuel consumption and improved efficiency.

Sports and recreation equipment manufacturers leverage the exceptional properties of UHMWPE in products like skis, snowboards, and protective gear. Its high abrasion resistance, impact strength, and flexibility make it a preferred choice for these demanding applications, ensuring durability and performance.

In industrial and chemical processing, UHMWPE is utilized for its excellent chemical resistance and low friction properties. It is commonly used for lining pipes, tanks, and chutes, protecting against abrasion, corrosion, and chemical reactions.

The food and beverage industry also benefits from UHMWPE's non-toxicity, low moisture absorption, and ease of cleaning. It is employed in the production of conveyor belts, cutting boards, and food processing equipment, ensuring hygiene, safety, and efficiency.

1.3 Advantages of UHMWPE in Various Industries

UHMWPE offers numerous advantages that make it highly desirable in various industries:

Exceptional Wear Resistance: UHMWPE exhibits exceptional resistance to wear and abrasion, making it ideal for applications that involve sliding, impact, or frictional forces.

High Impact Strength: With its high impact strength, UHMWPE can withstand heavy loads and absorb shocks, reducing the risk of component failure and increasing product lifespan.

Chemical Resistance: UHMWPE is highly resistant to chemicals, acids, and solvents, ensuring durability and longevity even in aggressive environments.

Low Friction Coefficient: The low coefficient of friction of UHMWPE reduces energy loss and enables smooth movement, making it suitable for applications where reduced friction is crucial.

Self-Lubricating Properties: UHMWPE has inherent self-lubricating properties, eliminating the need for additional lubricants in many applications, reducing maintenance and operational costs.

Biocompatibility: In medical applications, UHMWPE exhibits excellent biocompatibility, meaning it is well-tolerated by the human body. This makes it suitable for use in orthopedic implants and other medical devices, reducing the risk of adverse reactions or complications. Low Moisture Absorption: UHMWPE has low moisture absorption properties, ensuring dimensional stability and preventing degradation when exposed to moisture or humid environments. Electrical Insulation: UHMWPE possesses excellent electrical insulation properties, making it a preferred choice for applications requiring insulation and electrical components. UV Stability: UHMWPE is resistant to ultraviolet (UV) radiation, making it suitable for outdoor applications where prolonged exposure to sunlight is expected. Ease of Machining and Fabrication: UHMWPE is relatively easy to machine, fabricate, and process compared to other engineering plastics. It can be cut, drilled, and shaped into various forms, allowing for customization and efficient manufacturing processes. The advantages of UHMWPE make it an indispensable material in industries where durability, strength, chemical resistance, and low friction properties are critical. Its versatility and unique characteristics contribute to its widespread adoption and continued exploration of new applications.

In the following sections, we will dive deeper into the properties of UHMWPE, the manufacturing and processing techniques involved, as well as its specific applications in different industries. Stay tuned for a comprehensive understanding of this remarkable engineering plastic.