Polyethylene Glycol (PEG): Concepts, Applications, and Side Effects

Polyethylene Glycol (PEG) is a polymer compound produced from ethylene glycol through the combination of ethylene oxide molecules with it. It is one of the most important derivatives of petroleum, with a wide range of applications in various industries, from industrial to medical and even cosmetic and personal care. Due to its non-toxic and non-hazardous properties, it is used as a safe substance in various consumables. This article aims to explore the concepts, applications, and side effects of polyethylene glycol and provide comprehensive and useful information in this field.

Part 1: Introduction to Polyethylene Glycol

1. History and discovery of this compound:

Polyethylene Glycol was first discovered by Charles Edward Ballard in 1844. He prepared this compound from ethylene glycol as the main ingredient in anti-freeze. Since then, polyethylene glycol has been recognized as an essential and versatile substance in various industries.

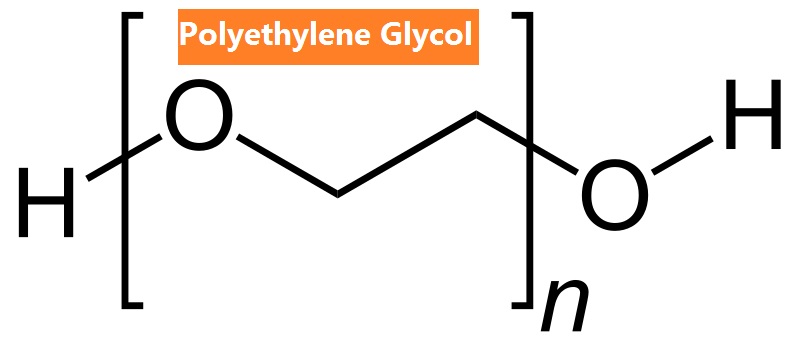

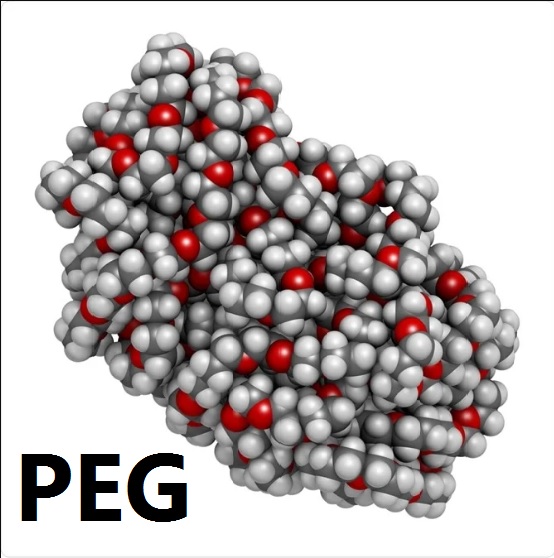

2. Structure and properties of polyethylene glycol:

Polyethylene Glycol is produced as a polymer molecule with a repetitive number of ethylene oxide groups. It possesses unique physical and chemical properties, making it a versatile and efficient material in various applications. Its properties include melting point, density, color, and odor, all of which are non-hazardous.

3. Behavior in water and solubility:

Polyethylene Glycol is known as a hydrophilic and soluble polymer. This characteristic makes it an effective lubricant and moisture-absorbent in cosmetic and personal care products. Additionally, it is used as a solvent in the formulation of some medicines and food products.

Part 2: Applications of Polyethylene Glycol in Industries

1. Use in formulating oils and organic insecticides:

Polyethylene Glycol is used as an effective lubricant in the formulation of oils. This feature makes it a useful solvent in organic insecticides as well. Furthermore, its high resistance to heat and moisture makes it a suitable choice for formulating products in this category.

2. Role as a color carrier in various industries:

Polyethylene Glycol is used as an effective color carrier in various industries, including dyes and resins. Its solvent and stability properties help preserve colors and resins in formulations, enhancing the quality of the products.

3. Applications in paper, textile, and ceramic industries:

In the paper industry, Polyethylene Glycol is used as a softening and pliable agent in paper formulations. This characteristic distinguishes it from other softening agents and makes papers more flexible and higher in quality. Additionally, Polyethylene Glycol is used as a drying time enhancer in industrial adhesives and paints.

Part 3: Medical Applications of Polyethylene Glycol

1. Polyethylene Glycol-based drugs and their uses:

Polyethylene Glycol is used in many osmotic-based drugs, including laxatives. These drugs facilitate digestion and waste disposal by increasing the density and volume of intestinal contents.

2. Industrial applications of Polyethylene Glycol in cosmetics and personal care:

Polyethylene Glycol is used as a lubricating and moisture-absorbing substance in creams, lotions, powders, and gels. These properties make cosmetic and personal care products more efficient and effective.

Part 4: Side Effects and Toxicity of Polyethylene Glycol

1. Investigating side effects and body tolerance in long-term use:

Ordinary and limited use of Polyethylene Glycol is safe and non-hazardous for most individuals. However, any unwanted symptoms or sensitivities, including digestive or allergic symptoms, should be reported to a medical professional for appropriate actions.

2. Studies on safety and toxicity of Polyethylene Glycol:

Research and safety studies show that Polyethylene Glycol is recognized as a non-toxic and non-hazardous substance, safe for human consumption. However, further studies are needed to investigate the long-term effects of this substance in the human body.

Polyethylene Glycol, as a derivative of petroleum with a wide range of applications in various industries, is known as a safe and non-hazardous substance. Its applications in industries, medicine, personal care, and food show its versatility and importance. Based on existing research and scientific studies, the appropriate and limited use of Polyethylene Glycol is safe and non-hazardous for most individuals. However, it is advisable to consult a medical professional for long-term consumption.

Read More: