A Comprehensive Comparison of Polyethylene and Polypropylene

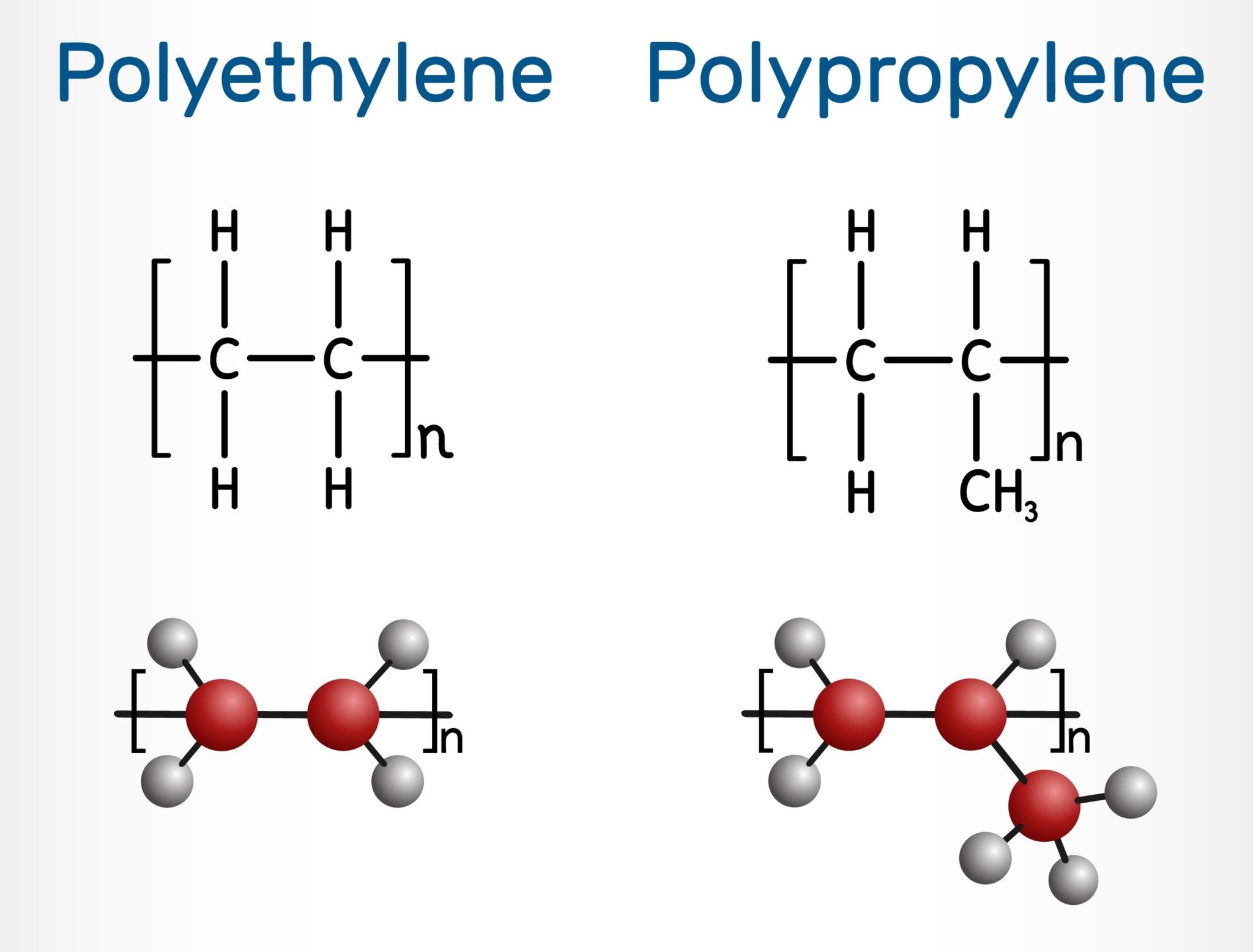

Polyethylene (PE) and

Polypropylene (PP), two plastics derived from petroleum, play a crucial role in our daily lives. While these two polymers may share some similarities, they each possess unique characteristics that distinguish them. In this article, we will delve into the properties, applications, and advantages of Polyethylene and Polypropylene, aiming to provide a comprehensive understanding for choosing the most suitable material based on specific needs.

Polyethylene (PE)

1. Applications and Ubiquity:

Polyethylene is recognized as the most widely used plastic globally. From plastic bags in the market to packaging and hygiene products, this plastic is omnipresent in various aspects of daily life.

2. Low-Temperature Resistance:

High resistance to low temperatures is a prominent feature of Polyethylene, making it suitable for applications such as packaging food or transport of goods.

3. Flexibility and Adaptability:

The high flexibility and adaptability of Polyethylene make it an ideal material for a wide range of products.

4. Cost-Effectiveness:

Lower costs compared to Polypropylene are a significant factor contributing to the popularity of Polyethylene.

5. Various Types:

One interesting characteristic of Polyethylene is its ability to produce different types, such as Linear Low-Density Polyethylene (LLDPE) or Branched Polyethylene. These features contribute to the creation of diverse products with various properties and applications.

Polypropylene (PP)

1. Lightweight and High-Temperature Resistance:

Polypropylene is lighter than Polyethylene and exhibits good resistance to high temperatures, acids, and chemical solvents.

2. Higher Resistance to Breakage:

Due to its higher resistance to breakage, Polypropylene finds applications in areas like construction elements or packaging of products.

3. Colorability and Adjustable Structure:

Polypropylene easily accepts coloration and shape alterations, providing versatility in design.

4. Diverse Applications in the Construction Industry:

Polypropylene is commonly used in the construction industry for manufacturing adhesive tapes, automotive components, and storage boxes.

General Comparison

1. Temperature Resistance:

- Polyethylene: Resistant to low temperatures.

- Polypropylene: Resistant to high temperatures.

2. Flexibility:

- Polyethylene: Flexible and adaptable.

- Polypropylene: Less flexible but more resistant to breakage.

3. Cost:

- Polyethylene: More economical.

- Polypropylene: Higher resistance to high temperatures increases costs.

4. Applications:

- Polyethylene: Packaging, plastic bags, transportation products.

- Polypropylene: Construction elements, adhesive tapes, automotive components, storage boxes.

Considering the prominent differences in properties and applications, the choice between Polyethylene and Polypropylene should be made based on the specific needs of each application. Each of these plastics, with its unique features and applications, contributes to improving efficiency in both daily life and industrial settings.

Read More: