Types of Polyethylene Tanks in Terms of Shape

-

Vertical Polyethylene Tanks: These tanks are produced in cylindrical shape and can be either plain or covered. Vertical polyethylene tanks can be installed on a smooth and stable surface or placed on a suitable base. However, for high-capacity vertical tanks, it may be necessary to construct a proper foundation to prevent ground settling. Vertical and horizontal polyethylene tanks find application in various industries such as agriculture, conversion, petrochemicals, industrial and semi-industrial centers, construction sites, labor camps, and hygiene product manufacturing facilities. Vertical polyethylene tanks are particularly important when industries require storage of large volumes of chemicals or face physical space constraints.

-

Horizontal Polyethylene Tanks: These tanks are produced in cylindrical shape and should be installed on a smooth and stable surface. They have internal arms that provide support. Horizontal polyethylene tanks with low height are suitable for installation in spaces with height restrictions.

-

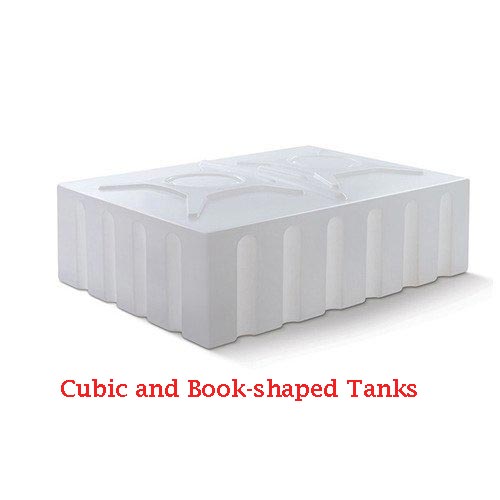

Cubic and Book-shaped Tanks: Cubic polyethylene tanks and book-shaped polyethylene tanks are among the other types of fluid storage containers. Cubic tanks are mostly rectangular cubes, while book-shaped models are thin (similar to rectangular cubes or book shapes). They are as resistant and robust as other polyethylene tanks. Book-shaped tanks are typically used in buildings where there is limited space for tank installation. Due to their slim body, book-shaped tanks easily pass through doors and low spaces, making them suitable for emergency water supply and fire-fighting in apartments. These tanks can be produced with 1 to 4 layers and are capable of storing various chemicals, oils, and food products. They are suitable for fluid transport, agricultural use, wheat storage, and storage of chemical, food, and pharmaceutical products.

-

Understep Polyethylene Tanks: These tanks are designed and produced in cylindrical or cubic shape. Industrial companies dealing with a range of raw materials and facing limited space for tank installation can make use of the space between stages. First, the dimensions of the understep installation area need to be measured, and then an appropriate capacity for the understep tank should be selected. It is important to maintain a minimum distance of 20 centimeters between understep tanks and the surface above them to allow for easy opening and closing of the tank's lid. Understep tanks are available in capacities ranging from 200 to 1500 liters and are also suitable for installation in spaces with angled walls. Cubic tanks, with their unique geometric shape and minimal use of existing space, have a considerable storage volume. The common feature among cubic, book-shaped, and understep polyethylene tanks is their ability to be installed in limited and unused spaces.

-

Conical Bottom Polyethylene Tanks: These tanks are used for storing various fluids, including water, but primarily for storing chemical fluids and industrial materials due to their conical bottom shape. The conical shape allows for complete and easy drainage of expensive and heavy fluids. These tanks are typically installed on a steel base to elevate them above ground level.

It is recommended to consult with experts or manufacturers for specific needs and recommendations regarding the selection and installation of polyethylene tanks.