Polyethylene Pipe and Earthquake

Earthquake Preparedness

HDPE PIPE – A LIFELINE IN THE AFTERMATH

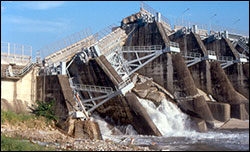

Can you imagine several weeks or even several days with¬out clean water, without sewer, or without natural gas, while severed pipelines are repaired following an earthquake? When you’re faced with an impending disaster, isn’t it only natural to take steps to prevent or minimize the catastrophe? Believe it or not, our towns and major metropolitan areas are on the cusp of such situations, but there are measures municipalities can put in place to lessen the damage impact.

Mayors should be concerned about compro¬mised pipelines during an earthquake event since almost every US state and Canadian province has experienced some earthquake activity. Most municipal pipe systems have not been designed to resist earthquake loads. Contractors and de¬sign consultants have not been required to ad¬dress these hazards in pipe systems, even though requirements and standards are established for buildings and other structures in seismic regions that do address these conditions.

One proven solution is to utilize high-density polyethylene pipe (HDPE) with its characteristic high ductility and ability to resist deflections from ground move¬ment. HDPEpipe systems can reduce or eliminate destruction, protect precious water lines for putting out fires, and maintain open communications when protected underground HDPEcon¬duit lines remain intact.

The benefits of HDPEpipe systems were demonstrated in Kobe, Japan during the earthquake of 1995 when 6,000 people perished and nearly half a million homes were destroyed. Osaka gas found failures in their steel and iron systems; but none where HDPEpipe was installed. For these reasons, Japan has been sys¬tematically replacing pipelines with HDPEthrough¬out the country wherever and whenever possible.

Other characteristics make HDPEpipe an ide¬al choice as well. Superior properties including abrasion and rust resistance, cost effectiveness, zero-leak capability and ease of installation earn it top rank as material-of-choice for gas compa¬nies worldwide. Today 95% of all gas service lines in North America count upon HDPEpipe’s reli¬able systems. And nuclear power plants are be¬ginning to transition to HDPEpipe use for safety and non-safety applications as the preferred op¬tion for new facilities. These critical-use applica¬tions rely on the steadfast ability of HDPEpipe systems to supply steady operation. HDPEpipe systems can sus¬tain your city’s most unsuspected upheaval during earthquakes and can provide a lifeline in their aftermath.

Other characteristics make HDPEpipe an ide¬al choice as well. Superior properties including abrasion and rust resistance, cost effectiveness, zero-leak capability and ease of installation earn it top rank as material-of-choice for gas compa¬nies worldwide. Today 95% of all gas service lines in North America count upon HDPEpipe’s reli¬able systems. And nuclear power plants are be¬ginning to transition to HDPEpipe use for safety and non-safety applications as the preferred op¬tion for new facilities. These critical-use applica¬tions rely on the steadfast ability of HDPEpipe systems to supply steady operation. HDPEpipe systems can sus¬tain your city’s most unsuspected upheaval during earthquakes and can provide a lifeline in their aftermath.

HDPE Pipe– Earthquake Simulation Tested

In addition to being tested during actual earthquakes throughout the US, Canada and the globe, Cornell University researchers simulated, on April 6, 2006, an earthquake’s effects on gas and water polyethylene (PE) pipes by exerting a 120,000-pound force on a 16-inch diameter, 35-foot-long pipe - the largest test of ground rupture effects that has ever been performed in a lab. The PEpipe, buried three feet below the surface, did not break during the test, but the sand shifted, bulged and cracked and created webbed lines on the surface as the pipe bent. Dur¬ing real life catastrophes PEpipe can be expected to perform well, while other pipe materials will be far more susceptible to breakage and lapse of service.

HDPE Pipes:

• A LEAK-PROOF SYSTEM - heat fused joints are as strong or stronger than the pipe itself and provide uninterrupted flow

• FLEXIBLE AND DURABLE - HDPE pipes are strong but pliable and well suited for dynamic applications including areas prone to seismic activity

• RUST–PROOF AND IMPERVIOUS TO BUILD-UP - does not support biological growth, provides no host for nutrients for bacterial or fungal growth and is the material of choice in harsh chemical environments

• ABRASION RESISTANT – does not easily pit, scratch or puncture

• LIGHT WEIGHT – easier to handle and install than rigid metallic or concrete pipe segments, allowing for huge cost advantages in the construction process

• COST EFFECTIVE - long term cost advantages due to its physical properties, leak free joints and reduced maintenance costs

Source: Plastics Pipe Institute

• Download the full text of Ployethylene Pipe and Earthquake