Design and calculation of manholes

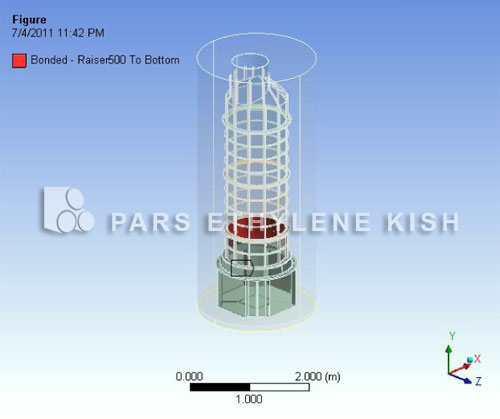

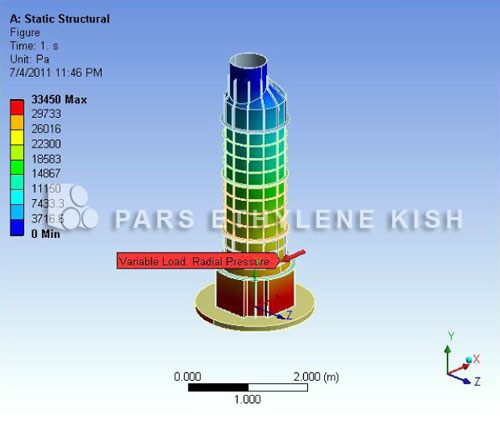

Polyethylene manhole analysis

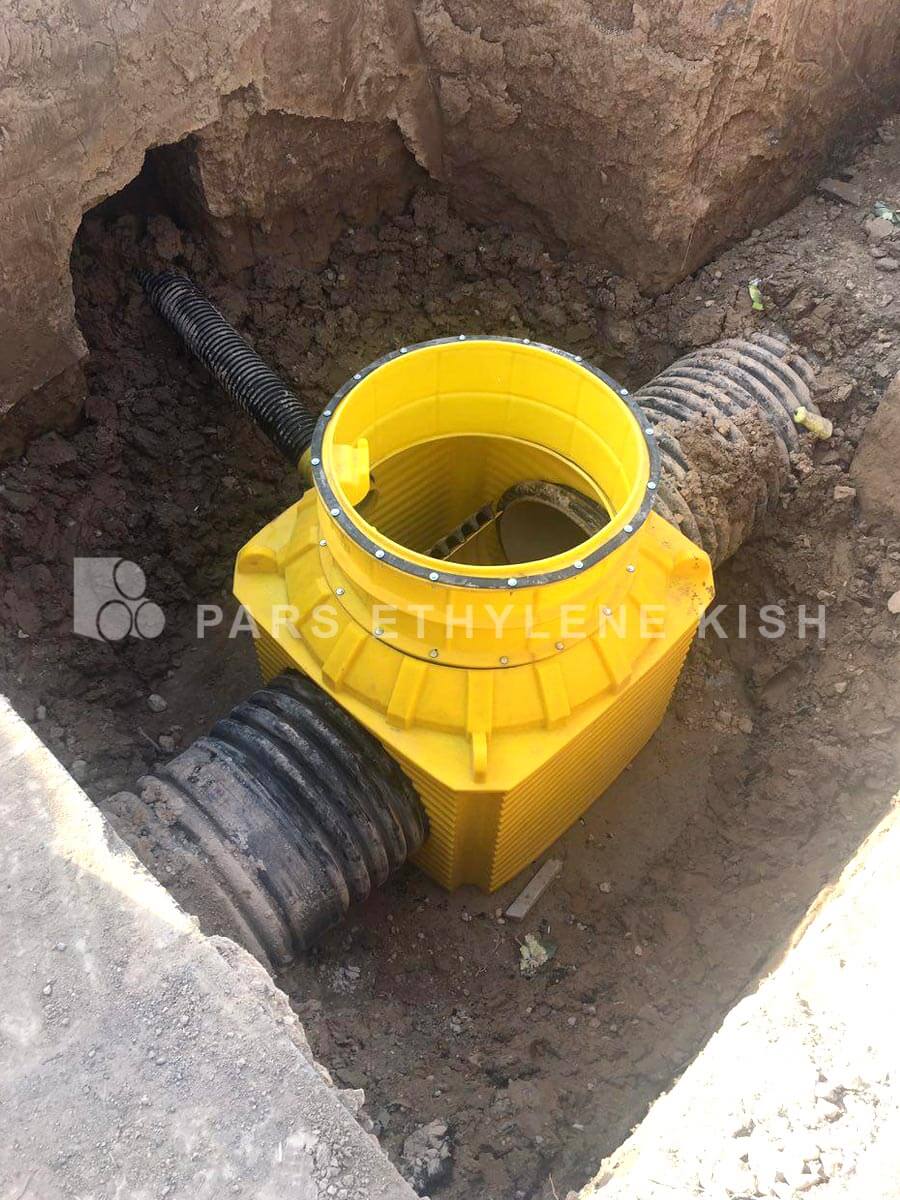

Production of polyethylene manholes is not the sole construction and commissioning of rotary machines for producing or procuring raw materials. Designing and calculating and how to make molds, analyzing and evaluating the manhole's body resistance is of great importance. Therefore, Pars Ethylene Kish has analyzed all the designs and drawings of molds and manholes before making and analyzing them and simulating actual conditions and introducing various types of traffic pressures and dead and live loads like those designed for special applications, strength, durability and precision of products, Pars ethylene Kish manholes are resistant and defective in any way.

Here is some of these calculations. Contact the engineering unit or sales expert at the company for a full version of the calculations.

Manhole calculations notebook

This report was prepared to investigate the resistances of a manhole body block of 1 meter, a base diameter of 1.2 meters and a length of 4.5 meters with a minimum thickness of 10 mm made of polyethylene. Structural analysis is done according to the actual conditions of installation of inside clay equipment with general specifications of Tehran soil. For Backfill, install the PE material and CLSM materials according to 99R - 229ACI standard has been used instead of peripheral soil. The choice of this material due to the limited space of installation in the urban tributaries and the impossibility of proper soil damage in the limited space. This limited analysis is based on the ASTM F 04 - 1759 standard is used for designing polyethylene manholes, which provides much more accurate results than manual calculations based on the approximate formulation available.

Specifications of materials in calculations

Polyethylene materials

The material used in the medium density polyethylene manhole is in accordance with the code -UA3840MD of Iranian petrochemical products with the specifications table provided by the factory (the material specifications table is available in the original version of the calculator). The production method of these materials is rotational molding.

Concrete

The bottom of the manhole, as well as the concrete slabs of the concrete, is used with the specifications specified in the calculation section. Since the upper slab is only a power transmitter to the perimeter of the manhole, the traffic load applied to this concrete slab directly enters the periphery of the manhole, which is, in fact, a prerequisite for engineering.

Concrete installed on the manhole floor is also assumed with the assumption of the proper loading of the same load as the concrete manholes available and transmits vertical loads from the manhole and CLSM and Backfill to the soil floor.

Clay

According to ASTM F 04 – 1759 standard, and also the request of the deserving employer of the perineum of manhole has been selected from unpolluted clay according to the environmental conditions of the installation site. (Material specifications available in the calculations notebook)

CLSM

According to the 99R-229ACI standard, specifications of material used for Backfill with a thickness of 30 cm around the manhole. (Material specifications available in the calculations notebook)

Other items in the manhole calculations notebook include the following: the results are available in the original version of the calculating system.

-

- dead loads

-

- live loads

-

- Documentation and software analysis and design

Contact the engineering department or sales expert at the company for a full copy of the calculations.