Ultrasonic

Dimension and thickness measurement device at production time

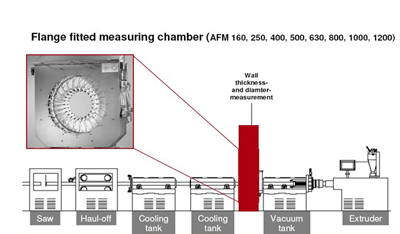

Ultrasonic (UltraSonic) is a device that is installed after vacuum tank, and its task is to measure thickness of the HDPE pipe from different points in the form of parallel and at the time of production. If the pipe has any inconsistency with defined standards, it will alert to the system, and stops pipe production line. Ultrasonic device is called ultrasound, and its existence on the polyethylene pipe production lines is required, and in the INSO standard for producing a gas polyethylene pipe, this machine is necessary, and it must be installed on the line and busy. Ultrasonic device has a separate monitoring system, and check pipe status at every moment. This system also has capability of coordination with other control systems of pipe line, including overall monitoring system, extruder control system and gravimetric control system, and in the event of an error, it gives required commands to other systems.

For many years ultrasonic or ultrasound systems have been and will be a precise and convenient system for measuring of thickness and diameter of polymeric wall pipes.

Basis of flawless and quality polyethylene pipe production, is accurate and momentous information from production process, which is evaluated by smart sensors and modern equipment, and this equipment affects entire production line and manufacturing process. precise and accurate assessment of the production process leads to production of a quality product and saves use of raw materials, and also, existence of accurate measuring equipment on the production line, makes customers and inspectors sure that, produced polyethylene pipes are dimensionally in full compliance with standards.

All production lines of polyethylene Pars Ethylene Kish equipped with ultrasonic equipment, and all these devices are made by INOEX Germany. INOEX Company has a long and brilliant history in the design, manufacture and production of measuring equipment for extrusion lines.

Ultrasonic device has various models that they are used according to need and position of the production line. Appearance and model of the ultrasonic device (ultrasound) is not important, and its performance, and its manufacturer is very important.

Suction Machine

Gravimetric

Extruder

Monitoring of polyethylene pipe production line

Polyethylene pipe mold

Vacuum Tank

Ultrasonic

Cooling Tank

Haul off of Polyethylene pipe

Polyethylene pipe marker

Saw

Tilling Table

PIPE Winder

Equipment for production line of polyethylene pipes and connections

Production line of single wall polyethylene pipes

Double wall polyethylene Corrugated Pipe production line